|

Products > Compressor Technique > Process Gas and Air Equipment > Centrifugal Compressors

|

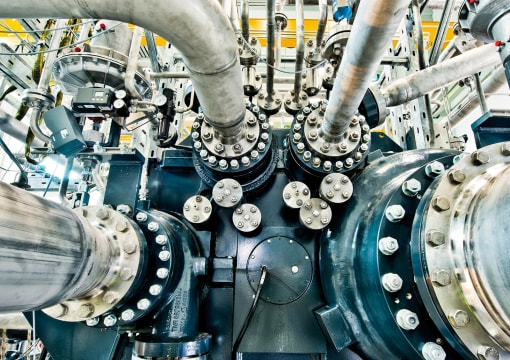

GT-Series centrifugal compressor for air and process gas applications

Atlas Copco GT-Series integrally geared centrifugal compressors feature innovative gearbox and impeller designs for air and process gas applications up to 205 bar.

Technical description GT-Series centrifugal compressorAtlas Copco Gas and Process has designed and commissioned thousands of centrifugal compressors worldwide. From air separation to oil and gas processes our compressors are built to boost efficiency and productivity. Designed in a compact package with minimum installation time, GT Series compressors handle flow volumes up to 480 000 m3/h and pressure of up to 205 bar. Our GT-Series compressor are configured up to eight stages, with required driver powers up to 37 MW. Driven by integral gear technology, GT Series centrifugal compressors increase your productivity with the industry’s most efficient and compact mechanical drive design. Add to that our highly-efficient and expertly tailored impellers, and you get an optimum solution for your specific application and process requirements. Boosting the compressors’ flexibility, options such as Variable Inlet Guide Vanes (IGVs) and Variable Diffuser Guide Vanes (DGVs) give greater process control and higher performance when conditions such discharge pressure, flow volume change. Central for many application scenarios, the GT Series centrifugal compressors are fully API compliant, built for a long service life, and backed by our global Aftermarket Services network.

|

T-Series centrifugal compressor for downstream applications

|

T-Series centrifugal compressors process reactor pressures of up to 40 bar (580.2 psi) and flow volumes up to 80 000 m3/h (47 086 cfm), powered by proven Atlas Copco technologies such as

T-Series compressors feature state-of-the-art dry gas seals as an alternative to oil-lubricated systems. Their outstanding safety reliability is also confirmed by American Petroleum Institute (API) certification according to standards API 617 and API 614. And, depending on your process, our experts around the globe can customize your turbo compressors – also matching API and local safety standards – to boost the safety and efficiency of your operation. |

Working in some of the world’s most demanding chemical and petrochemical applications, our T-Series compressors are trusted for efficient processing of polyolefines such as polypropylene and polyethylene. Built for maximum reliability they handle discharge pressures of 40 bar and flow volumes up to 80 000 m3/h (47 086 cfm).

|

RT-Series single-shaft radial compressor

Atlas Copco Gas and Process has over 100 years of air separation experience. It’s this expertise that we lean on when designing compressors for modern large-scale air separation units (ASU). Our robust single-shaft, three-stage radial-flow RT-Series compressor reaches new levels of stage and impeller efficiency and productivity for your main air application requirements.

Technical description of the RT-Series single-shaft turbocompressor

A direct answer to growing demand for larger and OPEX optimized air supply levels in today’s air separation units (ASUs), the single-shaft, three-stage radial-flow RT-Series combines the best in our aerodynamic competence to deliver ultra-efficient stage and impeller design. In full compliance with API 617 and 614 (oil system) standards, the RT-Series is developed for all main air separation applications. By using a modular, simplified design and a free-arrangement packaging concept the RT-Series compressors

|